Products • Compounding Lines

Compounding Lines

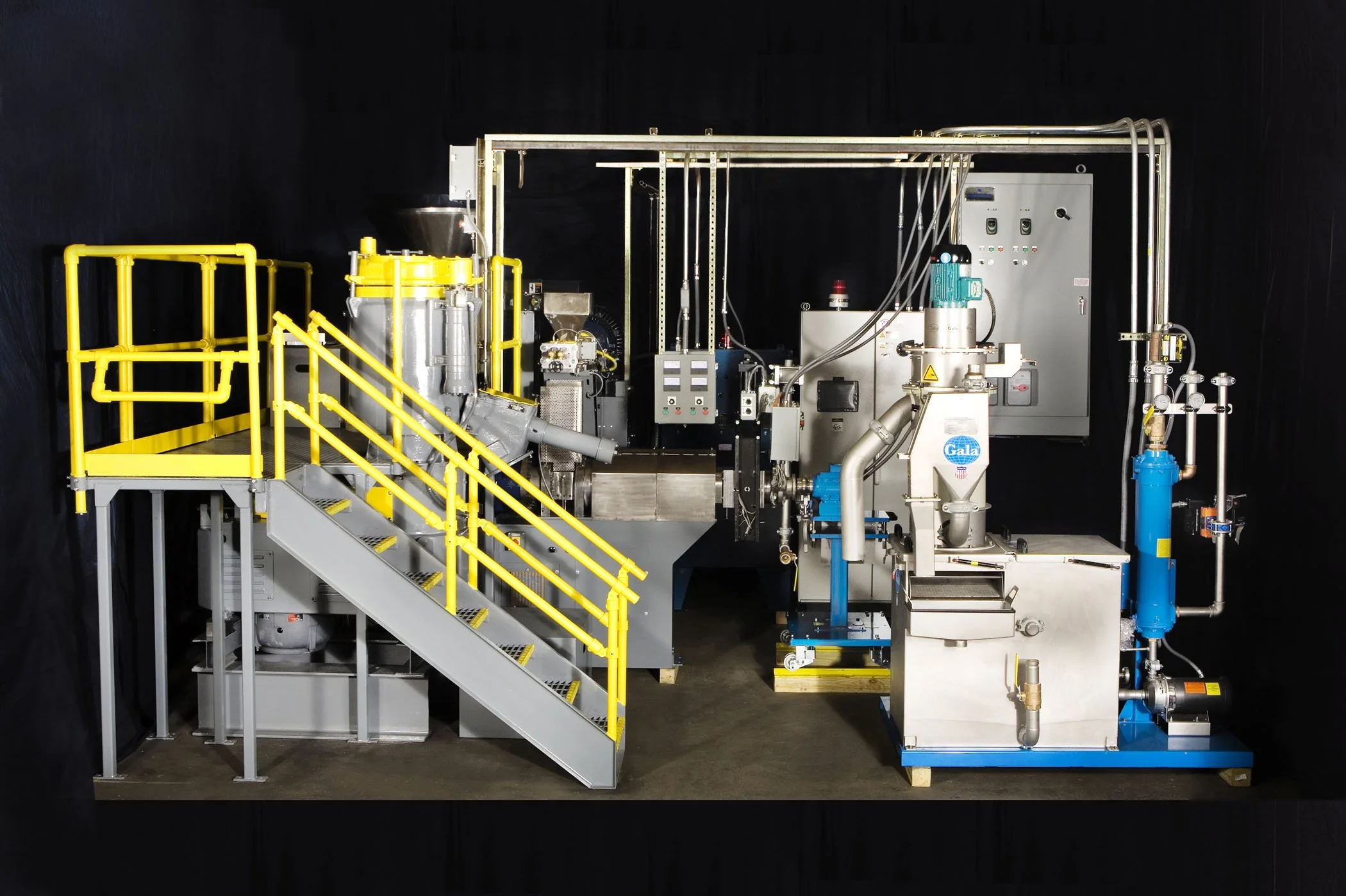

Fully integrated, interlocked compounding lines that pair TPEI continuous mixers with extruders,

controls, and downstream systems — engineered to process a wide range of thermoplastics and rubber

polymers at production rates from 50 to 15,000 lbs/hr.

Typical Line Architecture

- Continuous mixer and downstream extruder.

- Electrical control panel with interlocks and alarms.

- Lubrication and water cooling subsystems.

- Downstream options: screen changer, pelletizer, or die.

Processing Envelope

- Handles a wide variety of thermoplastics & rubber polymers.

- Ideal for acrylics, nylons, PC, polyesters, PVC, rubber, and hot-melt adhesives.

- Configured to customer specifications for throughput and product mix.

- Production rates from 50 to 15,000 lbs/hr, depending on line size.

Delivery & Procurement Options

- Turnkey Systems: complete lines with mixer, extruder, controls, utilities, and downstream equipment.

- Modular / Components: continuous mixers, extruders, control panels, lube & cooling systems, or downstream equipment supplied individually.

- Interlocked maintenance safety: alarms and automatic shutdown sequences built into the control philosophy.

- Engineered for new installations, retrofits, or expansion of existing compounding assets.