Engineering Reliability Since 1979.

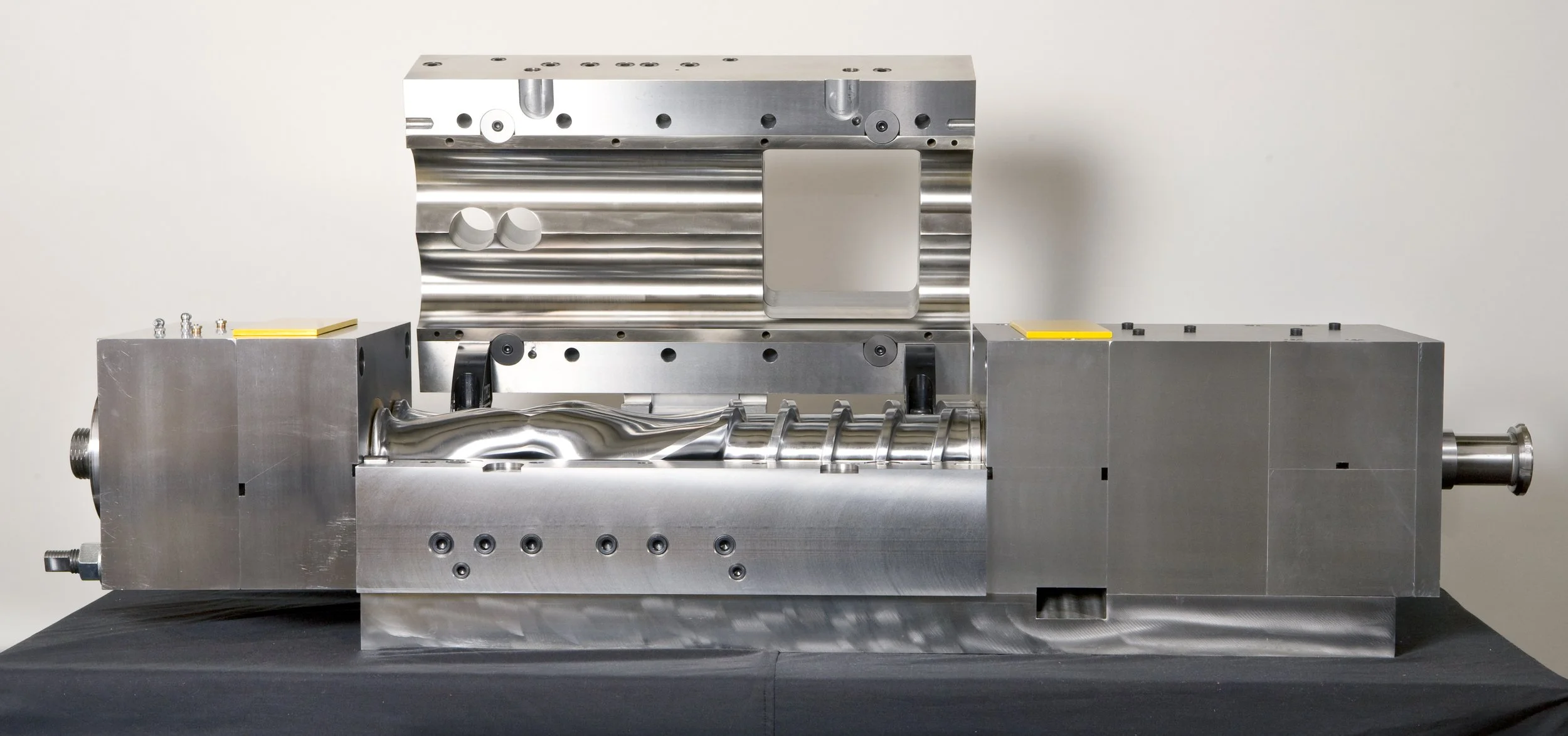

Technical Process & Engineering, Inc. designs, builds, and services continuous mixers, extruders, and turnkey compounding systems for the plastics and rubber industries. Since 1979, our mission has been simple: keep production running with dependable equipment and responsive support.

TPEI was founded when compounding lines were becoming more complex, but many plants were still fighting the same problems: chronic downtime, difficult maintenance, and equipment that was never quite matched to the process.

Our founders started TPEI with a clear idea: build machines that earn trust on the plant floor — not just on paper. That meant heavy-duty designs, serviceable components, and engineers willing to stand beside the equipment they built.

- First projects focused on continuous mixers for demanding rubber and plastics applications.

- Over time, the scope expanded to extruders, complete compounding lines, and turnkey systems.

- Today, TPEI supports customers through the full lifecycle: design, build, rebuilds, and 24/7 service.

Every machine we design has one job: run reliably in production. Everything else is negotiable — that isn't.

- Reliability over complexity: simple, robust designs beat fragile automation.

- Lifecycle thinking: we design for rebuilds, alignment checks, and future upgrades.

- Process fit: mixers, extruders, and controls are engineered to your material and throughput — not a generic spec sheet.

- Responsiveness: service, parts, and support are built into the way we work, not treated as an afterthought.

- Mixers that handle heavy-fill, temperature-sensitive work — designed specifically for plastics and rubber compounding.

- In-house machining, rotors, and parts — short lead times and precise fit for TPEI mixers and many legacy designs.

- Rebuilds and retrofits that extend machine life — gearboxes, rotors, controls, and alignment brought up to modern standards.

- Turnkey systems with interlocked controls — from mixer and extruder through downstream, utilities, and safety logic.

- 24/7 technical support — field service, emergency parts, and troubleshooting to keep lines running.

We know what it costs when a line goes down — lost production, missed delivery dates, and pressure on everyone from maintenance to engineering.

At TPEI, we believe manufacturers shouldn't have to suffer because equipment is outdated, unreliable, or poorly supported. Our goal is to help you run confidently with machinery that's built to last and backed by responsive, expert service.

- 1. Discuss Your Needs — we review production goals, materials, and existing equipment.

- 2. Engineer the Right Solution — new equipment, rebuilds, or retrofits are tailored to your spec.

- 3. Build, Install, and Commission — systems are assembled, tested, and supported through start-up.

- 4. Support for the Long Term — parts, rebuilds, and service keep your line productive for years.

When a customer's mixer failed in the middle of a critical production run, their entire schedule was at risk. Within the hour, our team had reviewed photos, confirmed the failure mode, and located a compatible rotor assembly in stock.

By morning, the part was on site and installed. The line came back up, and the customer kept their delivery commitments. That's what we mean by engineering reliability — not just in the equipment, but in how we respond when it matters most.

Our Promise

At TPEI, "Customer Service, Compounded Daily" is more than a tagline. From first design review to decades of service, we're committed to helping your operation stay efficient, reliable, and profitable. When you partner with TPEI, you're not just buying a machine — you're gaining a team dedicated to keeping your production running without interruption.